Your Expert Custom RFID Tag Manufacturer in Spain: The Complete Guide to RFID Technology and Solutions</h2

Imagine having x-ray vision of every product, every asset, every movement within your company. A world where shrinkage is minimal, inventory errors are a thing of the past and operational efficiency reaches levels that once seemed unattainable. This is not the future; it is the reality that RFID technology is already making possible today. In a globalised and ultra-competitive marketplace, having a fail-safe inventory management, traceability and supply chain is not a luxury, it is the foundation for survival and growth.

But how do you navigate the complexity of this technology, how do you know which RFID solution is right for your specific challenges, your industry, your particular environment? This is where experience, knowledge and manufacturing capability make the difference. At Trace-ID, we understand your challenges because we’ve been dedicated to RFID technology for years. We don’t just design and manufacture the highest quality RFID consumables here in Spain; we are passionate about helping you understand and unlock the incredible potential of RFID in your business. Get ready for a deep dive into the world of RFID from your trusted experts.

Unlocking the Heart of RFID Technology: How It Really Works and Its Essential Components

Beyond the simple idea of “radio identification”, RFID technology is an ingenious system. Understanding its fundamentals will help you appreciate why it is so powerful and versatile.

The Three Pillars of an RFID System

Every RFID system is built on the intelligent interaction of its components:

-

The RFID Tags (Tags): The Intelligent Data Carriers: Think of them as small storage and communication devices. Each RFID tag consists of at least two essential parts:

-

RFID Readers: The Communication Gateway: These are the devices that initiate the process. They emit radio waves at a specific frequency to “wake up” and communicate with the RFID tags within their coverage area. Readers can be fixed (installed on gates, conveyor belts) or mobile (handheld readers, on forklifts).

-

The Reader Antennas: Amplifying the Signal: These antennas, connected to the reader, are what emit and receive the radio signals in a given area. Their shape, size and polarisation directly affect the coverage area and the reliability of RFID tag reading.

How Interaction Works: The Science Behind the Magic of RFID

The RFID reading process varies slightly depending on whether the tag is passive or active, but the basic principle involves radio waves:

-

In Passive RFID (UHF, HF, LF): The reader emits a radio signal. When a passive RFID tag enters the radio frequency field of this reader, the tag’s antenna picks up that energy and uses it to power its chip. The chip then sends the stored information back to the reader through its antenna (a process called “backscatter” in UHF).

-

In Active RFID: The tag has its own power source. It simply waits for an activation signal from the reader or transmits data at regular intervals. Its battery allows for a much longer read range.

RFID Frequencies and Standards: Choosing the Right Language

We have already mentioned the frequencies (LF, HF, UHF), but it is vital to understand that each has its own standards (communication protocols) that ensure interoperability between different RFID equipment manufacturers.

-

UHF RFID (860-960 MHz): The most common standard for the supply chain is EPC Global Gen2 v2 (ISO 18000-6C). It allows remote reading, high speed and reading of multiple tags simultaneously (anti-collision). It is the key frequency for large-scale traceability and inventory management.

-

HF RFID (13.56 MHz): Standards such as ISO 14443 (for proximity cards, NFC) and ISO 15693 (for wider range applications, such as libraries or ticketing).

-

LF RFID (125 kHz): Mainly for access control and animal identification (ISO 11784/11785).

Understanding these frequencies and standards allows us to select the right RFID consumable and hardware to ensure that the entire RFID system works in harmony.

Quantifiable Benefits of Implementing an RFID Solution: Real Impact on Your Bottom Line</h2

Moving from a manual system (barcodes, pen and paper) to RFID is not just a technological upgrade; it is a strategic investment with a measurable return on investment (ROI).

Dramatic Improvement in Accuracy and Efficiency

-

Inventory Accuracy: Companies adopting RFID report inventory accuracies in excess of 95%, often approaching 99-100%. Compare that to the 60-70% typical of manual systems. This reduces losses from obsolete stock, theft (known as shrinkage) and shipping errors.

-

Operational Speed: Counting thousands of items that used to take hours or days is now done in minutes. Processes such as receiving goods are greatly streamlined, freeing up loading docks and reducing downtime.

-

Reduced Human Error: Automated scanning eliminates the eyestrain and typing errors associated with manual or barcode systems.

Unprecedented Visibility and Traceability

-

Real-Time Traceability: Know where each asset or product is at every key moment in the supply chain or within your facilities.

-

Detailed Traceability: Record the complete history of an item (origin, movements, transformations). Vital for quality management, product recalls and regulatory compliance.

-

Better Decision Making: With accurate, real-time data provided by the RFID system, you can make faster, more informed decisions about replenishment, logistics, production, etc.

Tangible Cost Savings

-

Labour Reduction: Less time spent on manual counting or individual scanning.

-

Stock Optimisation: Reduction of excess inventory and elimination of stock-outs.

-

Loss Prevention: Less losses due to theft, counterfeiting or expiry through better management.

-

Logistics Efficiency: Less urgent transport costs, better use of resources.

Boosting the Customer Experience (especially in Retail).

-

Product Availability: More accurate in-store inventory means customers find what they are looking for.

-

True Omnichannel: Facilitates services such as Buy Online, Pick Up In Store (BOPIS) or ship from shop, as you know exactly what is in stock.

-

In-Store Interactions: Enables smart fitting rooms or RFID-enabled information kiosks.

These benefits are not theoretical; they are proven results that companies achieve by strategically implementing RFID solutions.

RFID Applications in Depth: How Technology Shapes Entire Industries (And Trace-ID Solutions)

RFID’ s versatility is one of its greatest strengths. Let’s explore how it is applied in some of the sectors where Trace-ID has in-depth knowledge and tailored solutions.

RFID in Supply Chain and Logistics: The Operational Brain

Logistics is perhaps where RFID shines the brightest, digitising and automating critical flows:

-

Automated Receiving and Dispatch: Reads pallets, cases or bulk items as they pass through RFID portals, verifying delivery notes automatically.

-

Intelligent Warehouse Management: Locates items in real time, guides picking operators, optimises routes.

-

Returnable Asset Management (RTI): Traceability of pallets, containers, barrels. Ensures their return, optimises their life cycle and reduces replacement costs.

-

Efficient Cross-Docking: Streamlines the flow of goods without going through intermediate storage.

-

Yard Management: Monitors the arrival, location and departure of trucks and trailers.

Trace-ID provides the robust, high-performance UHF RFID tags required for these dynamic environments.

(Consider linking to Logistics Case Studies or RFID Products for Logistics pages.)

RFID in Retail and Fashion: The Shopping Experience and Stock Revolution

Retail has been one of the big drivers of mass RFID adoption at item level:

-

Item Level Inventory Accuracy: Conduct complete shop inventories in minutes (instead of days) with greater than 98% accuracy. This is the foundation of a successful omni-channel operation.

-

Loss Prevention: Discreet, secure RFID tags are an effective anti-theft tool.

-

Efficient Store Management: Improve replenishment, locate items for customers, manage returns quickly.

-

Smart Testers: Display information about the items the customer tries on, suggest complements, order other sizes.

-

Streamline Point of Sale: Some solutions allow faster checkout by reading all items in a basket at once.

Trace-ID manufactures retail and textile RFID tags, designed to be discreet, secure and with high read performance in high product density environments.

RFID in the Food Industry: Ensuring Safety and Traceability from the Field to the Table

Food safety is paramount. RFID provides the necessary traceability and control:

-

Detailed Traceability: Record every step of a food product: ingredient origin, processing, dates, batches, transport temperatures, destination.

-

Cold Chain Management: Monitor temperatures with RFID tags with integrated sensor.

-

Shelf Life Management: Controls stock based on expiry dates to minimise shrinkage.

-

Counterfeit Prevention: Ensures authenticity of high-value products.

-

Adaptation to Difficult Environments: Humidity, salinity or low temperatures in the food industry are a challenge. At Trace-ID, we are experts in designing RFID tags that work perfectly in these conditions. Our RFID tags for hams and sausages are an example of how we solve unique challenges.

We are pioneers in food RFID in Spain, offering RFID consumables that comply with the strictest regulations.

RFID in Asset Management: Total Control over Your Valuable Assets

Losing or not locating a valuable asset can cost time and money. RFID offers a robust solution:

-

Automated Asset Inventory: Perform quick and accurate audits of equipment, tools, furniture, IT devices, etc.

-

Rapid Location: Find specific assets in large facilities or multiple locations.

-

Usage and Maintenance Control: Associates usage data or maintenance history to the asset’s RFID tag.

Exploring Other Critical RFID Applications

RFID’ s adaptability allows it to solve problems in many other sectors:

-

Manufacturing (WIP – Work In Process): Track components and semi-finished products along the production line, optimising flows and controlling quality.

-

Health: Secure patient identification (RFID wristbands), tracking of high-value medical equipment, management of laboratory samples, traceability of pharmaceutical products.

-

Document Management: Traceability of files and important documents in large archives or libraries.

-

Access Control and Event Management: Badges or RFID wristbands for secure access, zone management, or even contactless payments.

-

Industrial Laundry Management: RFID tagging of work clothes or linen for tracking, inventory and wash cycle control.

-

Automotive: Traceability of parts, vehicle tracking on the assembly line or in the field.

For each of these applications, the choice and design of the right RFID tag is critical, something Trace-ID is an expert in.

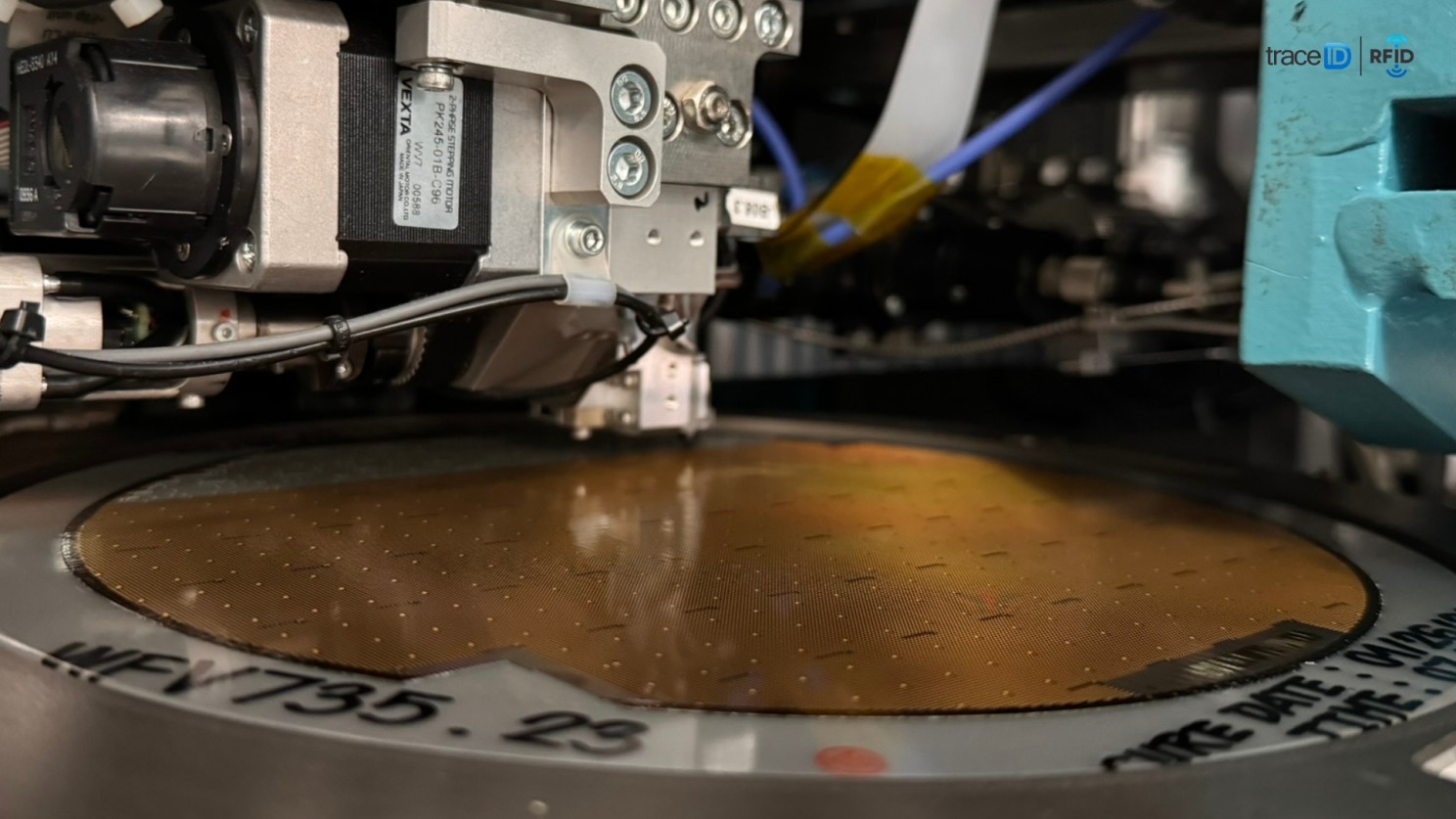

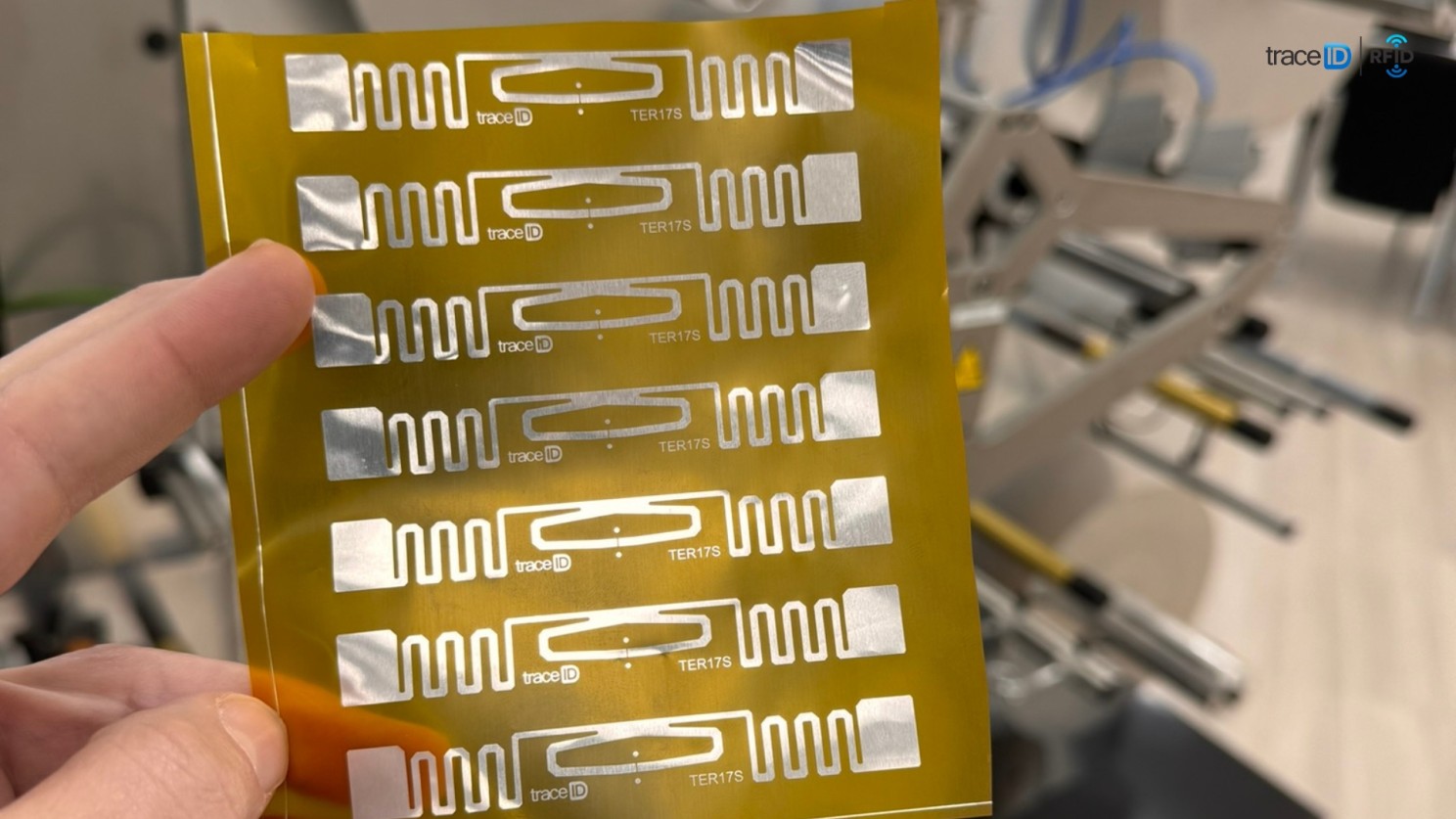

RFID chip wafers

RFID chip wafers

The ‘Trace-ID Factor’: Why Our Spanish Manufacturing Makes the Difference in Your RFID Project

In a globalised market, it’s easy to find suppliers of RFID consumables. But finding a partner that understands your needs, controls quality at source and offers real responsiveness is what sets Trace-ID apart. We are Your Expert Custom RFID Tag Manufacturer in Spain.

Total Control: Our RFID Manufacturing Process, Step by Step

Being a manufacturer means controlling every detail. Our process at our facilities in Spain includes:

-

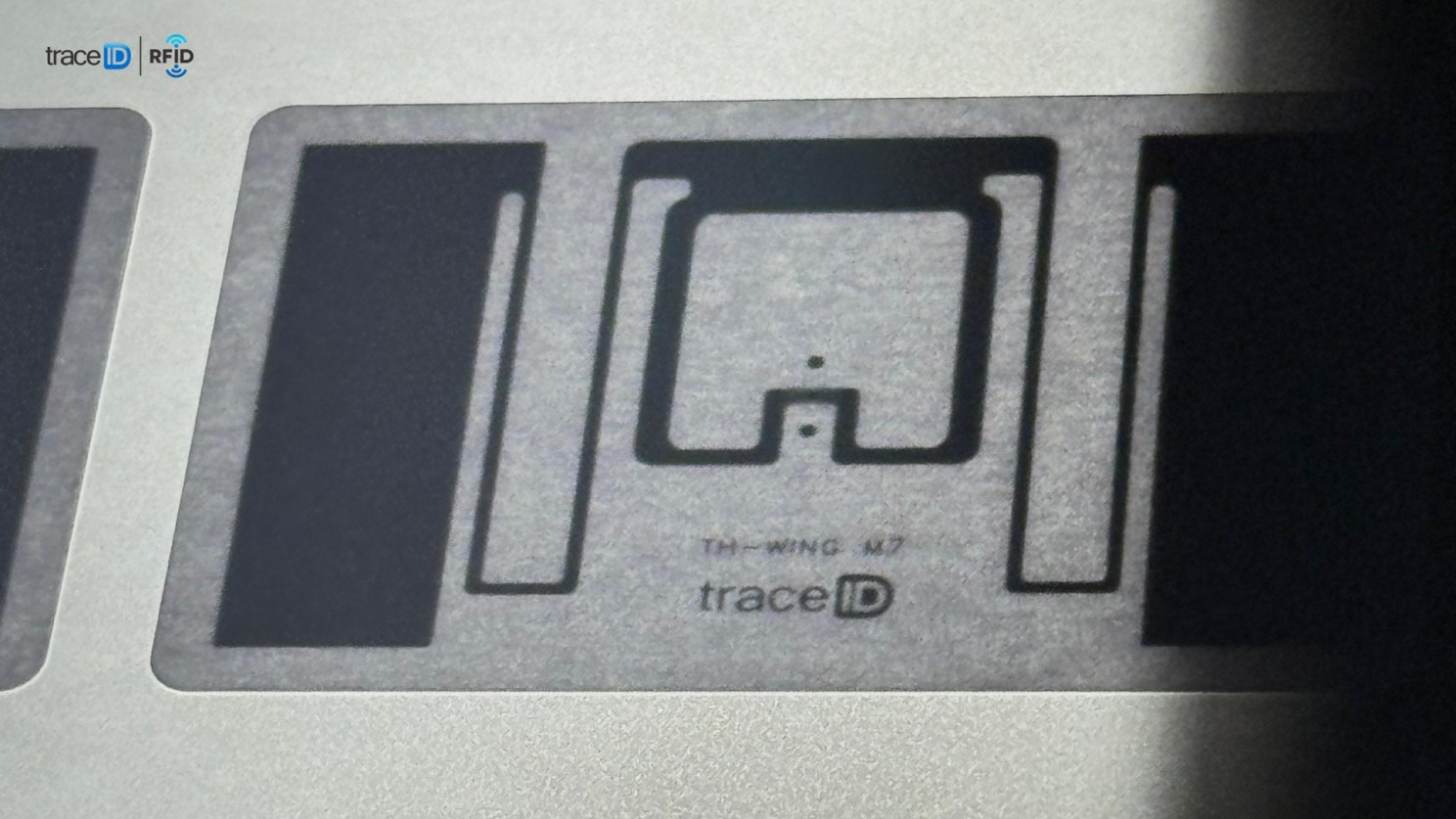

Antenna Design and Simulation: We do not limit ourselves to standard designs. Our R&D team designs and simulates antennas optimised for the frequency (UHF, HF) and the application environment (on metal, liquids, etc.).

-

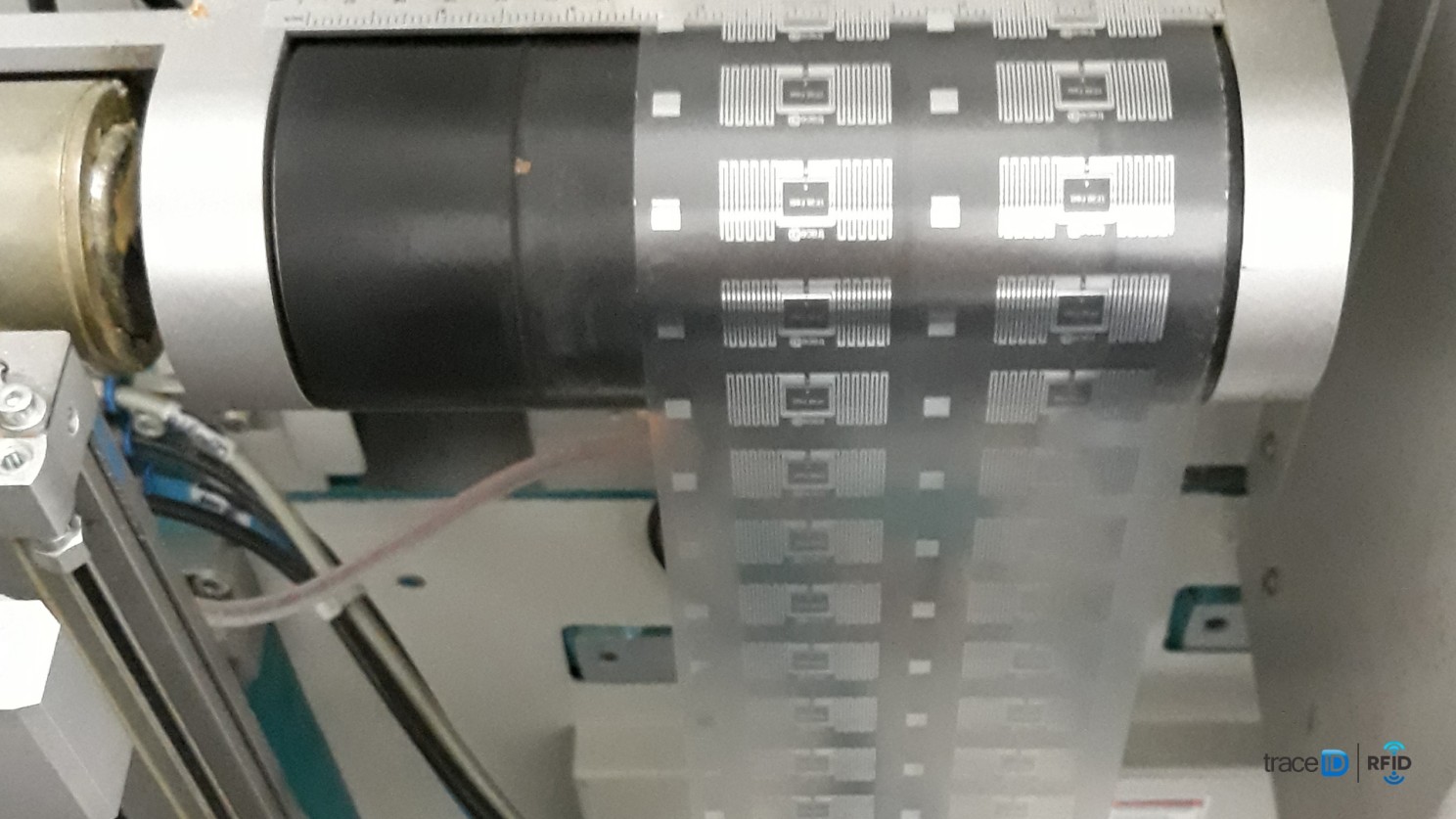

Inlay manufacturing: We produce the heart of the tag, bonding the chip to the antenna on a substrate. Precision here is vital to the performance of the RFID tag.

-

Conversion: We transform the inlays into the final format you need: adhesive labels of various sizes and materials, hangtags, cards, etc. This includes the choice of adhesives (for difficult surfaces, high/low temperatures), label materials (paper, PET, synthetics, special materials for resistance) and formats.

-

Advanced Customisation: We print (texts, logos, barcodes), encode (we engrave specific data on the chip of each RFID tag) and serialise the tags according to your exact requirements.

-

Exhaustive Quality Control: Each batch of RFID consumables undergoes rigorous testing to ensure that each tag is readable and meets specifications. Our Spanish quality standard is your guarantee.

This end-to-end control allows us to guarantee the quality and performance of every RFID tag we manufacture.

True ‘Made to Measure’ Capability: RFID Solutions No One Else Offers You

Herein lies our greatest strength as an expert manufacturer: solving challenges where standard tags fail.

-

RFID On-Metal Tags: Antenna design and use of special materials to make the RFID tag work efficiently even when attached to metal surfaces (a common challenge in RFID).

-

Labels for Wet or Liquid Environments: Development of labels and adhesives that withstand humidity and allow RFID reading despite the presence of liquids.

-

High Resistance Labels: Manufacturing RFID labels that withstand extreme temperatures, chemicals, abrasion or rough handling.

-

Special Formats and Adhesives: We adapt the shape, size and type of adhesive of the RFID tag to integrate it perfectly into your product or process.

If you have a particular requirement or environment that seems incompatible with RFID, come and talk to us. Chances are we’ve solved something similar or can design the perfect solution for you. We’re your partner for bespoke RFID.

Trace-ID as Your Strategic RFID Partner

We don’t want to be just your RFID tag supplier. We want to be your trusted partner in your journey towards digitisation with RFID.

-

For System Integrators: We offer in-depth technical support, access to our facilities for testing, samples, training and the assurance of a reliable supply of high quality RFID consumables that will make your projects shine.

-

For End Users: We provide expert consultancy to help you define your needs, select the right RFID system (hardware + consumables), and walk you through the implementation process, ensuring that the RFID solution works seamlessly in your operation.

Our knowledge and proximity, as a manufacturer in Spain, allows us to offer a unique collaboration.

Our RFID Tags

Our RFID Tags

Your RFID Project: A Guided Path from Concept to Successful Operation with Our Experts

Implementing RFID is a project. And like any project, it requires a methodology. At Trace-ID, we guide you through the key phases to ensure the success of your RFID system:

Phase 1: Needs Assessment and Solution Design

-

Understand your challenges: What do you want to improve (inventory, traceability, efficiency)?

-

Environment analysis: Remote visits or surveys to identify factors that may affect RFID reading (metals, liquids, interference).

-

Architecture definition: Recommend the frequency (UHF, HF), the type of RFID tag, the hardware (readers, antennas, RFID printers) and the necessary software.

Phase 2: Selection and Manufacturing of RFID Consumables

-

Designing the perfect RFID label: Based on phase 1, we define materials, adhesives, size, shape.

-

Custom manufacturing: We produce your personalised RFID tags in our facilities in Spain, with the necessary quality control.

-

Encoding and personalisation: We pre-engrave data on your RFID tags if necessary.

Phase 3: Pilot Testing and Optimisation

-

Deployment in a controlled area: Implement the RFID solution in a small part of your operation to validate its performance.

-

System tuning: Optimise reader/antenna placement, reader configuration and RFID tag design based on the results of the pilot.

Phase 4: Large Scale Deployment and Integration

-

Full Implementation: Deploy the RFID system in all target areas.

-

Software Integration: Connect the RFID platform with your existing systems (ERP, WMS, WMS).

-

Training: Ensure your staff knows how to operate the new RFID system.

Phase 5: Ongoing Support and Expansion

-

Post-Implementation Support: We are here to answer questions and ensure the continued operation of your RFID solution.

-

Maintenance and consumables replenishment: Reliable supply of RFID tags.

-

Identify new opportunities: Helping you expand the use of RFID to other areas of your business.

Our RFID Tags

Our RFID Tags

Overcoming Common RFID Challenges with Trace-ID’s Expert Knowledge

As with any technology, challenges can arise. But with the right partner, they become surmountable obstacles.

-

Interference: Metals and liquids can absorb or reflect RFID signals. Our expertise in antenna and material design, and testing in real-world environments, allows us to create RFID tags that mitigate these effects.

-

Read Density: Reading many RFID tags close together requires the right protocol (EPC Gen2 v2) and efficient anti-collision algorithms, something our RFID inlays and associated software handle well.

-

System Integration: Connecting RFID data with your existing software is key. Our technical team can advise and assist in this process.

-

Incorrect Consumable Selection: Using the wrong RFID tag for an environment can lead to project failure. Our evaluation and customisation phase avoids this problem.

Our experience as an expert RFID manufacturer in Spain allows us to anticipate and solve these challenges, ensuring the reliability of your RFID system.

Our RFID Tags

Our RFID Tags

Calculating the Return on Investment (ROI) of Your RFID Project: Justifying the Investment

Investing in RFID requires an initial outlay. But the savings and efficiencies it generates often quickly justify it. To calculate ROI, consider:

-

Implementation Costs: RFID hardware (readers, antennas, printers), RFID consumables (tags, inlays), RFID management software, installation cost, training, integration.

-

Annual Benefits (Savings and Gains): Labour savings due to automation. Reduction of losses (shrinkage, expiry). Reduction of unnecessary safety stock. Savings in logistics costs. Increase in sales (in retail due to better availability). Reduction in shipping/receiving errors. Savings due to better asset management.

The payback period for RFID projects is often between 6 and 24 months, depending on scale and sector. We can help you model this calculation for your particular case.

The Future of Traceability and Efficiency: Where RFID Technology Is Heading

RFID technology is not static; it is constantly evolving and converging with other key technologies:

-

RFID and IoT: RFID tags become passive “sensors” that power Internet of Things platforms, providing location and identification data for billions of everyday objects.

-

RFID and AI: Artificial Intelligence can analyse the huge volumes of data generated by RFID systems to optimise routes, predict demand, identify anomalies and improve automated decision making.

-

RFID and Blockchain: For applications that require absolute trust and security in traceability (e.g. luxury goods, pharmaceuticals, food), RFID can record events in an immutable blockchain.

-

New Sensor Types in RFID Tags: Integration of temperature, humidity, shock, etc. sensors into passive or semi-passive tags for more complete monitoring without the need for bulky batteries.

Trace-ID is at the forefront of these trends, researching and developing RFID consumables and solutions that will allow you to take advantage of these future innovations.

Conclusion

We have taken an in-depth look at the RFID universe . From its technological foundations to its transformative applications and exciting future. It is clear that RFID is not just a tag or a reader; it is a master key to optimisation, transparency and competitiveness in almost any industry.

However, the success of your RFID project depends largely on choosing the right partner. You need someone who doesn’t just sell you the components, but who understands your unique challenges, knows how the technology performs in your particular environment, and can manufacture the exact RFID solution you need, with the quality and reliability you expect.

At Trace-ID, we are Your Expert Custom RFID Tag Manufacturer in Spain. We know the technology inside out, we control the manufacturing process from start to finish and, most importantly, we are committed to being the partner that guides and supports you through every step of your RFID project .

Are you ready to leave behind outdated methods and embrace the efficiency, accuracy and visibility that only RFID can offer? Are you looking for an RFID tag manufacturer in Spain with the experience and true customisation capabilities to make your most ambitious project a reality?

Look no further. Let’s talk.

Contact our team of RFID specialists at Trace-ID today. Tell us what’s keeping you up at your operation. Explore with us how our custom RFID tags and our expert knowledge can become the solution you’ve been looking for. We are here, in Spain, ready to help you build the future of your business with RFID.

Contact us for more information focused on your needs. If you wish to receive information about RFID technology, subscribe to our magazine.