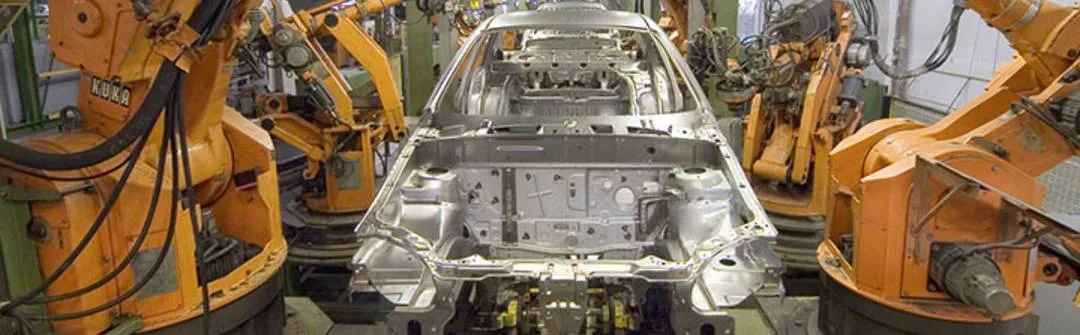

RFID tags for production processes in the automotive industry

In the automotive industry, the use of RFID tags and RFID reading and writing devices is growing day by day at every step of the production processes, because it is the most reliable way to identify the parts that correspond to each car configured by each customer.

An RFID system can cover every identification need of every plant task from metal plates workshop until the car leaves the factory. The majority of personalizations of a car materialize during assembly, so there are many versions of the same model in the production line. With RFID solutions, the identification of each piece and each car is accurate and updated in real-time.

The RFID technology is not only reliable and fast, but it is also very resistant to the roughness of manufacturing, such as high temperatures or corrosive substances. The RFID tags that are used in this sort of industrial implementations are single-use labels which are usually destroyed during or at the end of the manufacturing process.

RFID tags suitable for automotive production processes

On the one hand, there are RFID tags that will work on metal (which interferes with the operation of radiofrequency waves), and on the other, those that will be on hard plastics, glass and other materials.

In addition, the materials in which the inlay should be (RFID antenna with a chip inserted on a substrate) must be resistant to the appropriate temperatures and to the substances used in manufacturing.

The RFID tags that work on metal adhere to the piece and are usually on a material that separates the metal antenna from one to two millimetres, so that it does not interfere with the performance of the RFID tag. Another solution to label with RFID metal parts is to use flanges so that the label is hung and not attached to the sheet, but this solution is not always possible due to issues such as the type of handling of the parts.

As for the RFID tags that are going to adhere to hard plastic parts, these are adhesive RFID tags that do not need that distance between the piece and the antenna.

If you need more information about RFID tags for production processes please contact us, we are pioneer manufacturers in Europe and unique in Spain of RFID tags.

Author of the main photography: Mixabest

Contact us for more information focused on your needs. If you wish to receive information about RFID technology, subscribe to our magazine.